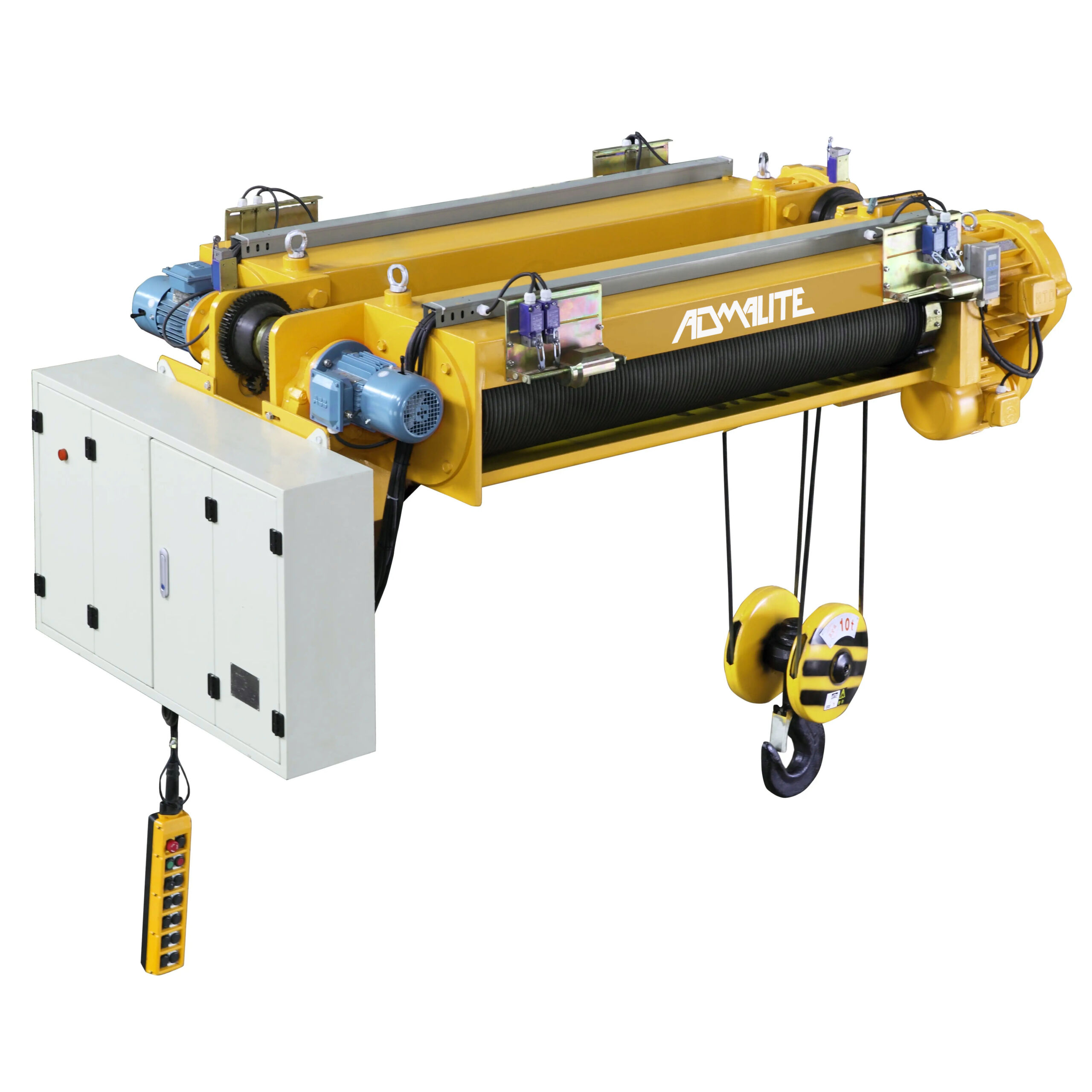

Admalite proudly designs and builds custom industrial control panels for material lifting equipment, including Overhead Bridge, Jib Cranes, and Hoists. In this comprehensive guide, we delve into the intricacies of control panels, highlighting their importance and functionality. Our goal is to position this article at the forefront of Google search results, providing valuable information and addressing common questions.

Understanding Overhead Bridge, Jib Crane, and Hoist Control Panels

Control panels are the heart of any lifting system, ensuring safe and efficient operation. Whether it’s an overhead bridge crane, jib crane, or hoist, the right control panel can significantly enhance performance and reliability.

Key Features of Admalite Control Panels:

- Custom Design: Tailored to meet specific requirements.

- High Safety Standards: Minimum safety factor of 4:1.

- Comprehensive Testing: Load tested for safety and reliability.

- Advanced Technology: CAD software for precise design and load testing.

Why Choose Admalite Control Panels?

Admalite control panels are designed with the highest standards in mind. Each panel undergoes rigorous testing to ensure it meets the specific needs of your lifting equipment. Here are some reasons to choose Admalite:

- Reliability: Built to last with durable components.

- Flexibility: Customizable to fit various applications.

- Ease of Use: Simple installation and maintenance.

Standard HOIST/LIFTING MOTION Control Panels

Our Standard HOIST/LIFTING MOTION Control Panels Include:

- Invertek® Variable Frequency Drive: Ensures precise control.

- Closed-Loop Vector Drive or Contactor Motor Controls: Offers flexibility in control methods.

- Voltage Compatibility: Panels available for 208-230, 385-415, 460, and 575 VAC; VFDs programmable for 50, 60, or 120 Hz.

- Standard Allen-Bradley Control Components: Option to use other brands if required.

- NEMA Type 12 Enclosures: Standard sizing per requirement.

- Branch Fusing and Motor Thermal Overload Protection: Designed to NEC specifications.

- Braking Contactors: As required by application.

- Removable Sub-Panel Components: For ease of maintenance.

- 105°C Rated Panel Wiring: With computer-generated labels on both ends.

- Common Raised Terminal Strip: Simplifies installation.

- Duct Channels for Main Wire Runs: Organizes wiring efficiently.

- Factory Inspected and Fully Tested: Ensuring quality and reliability.

- Regeneration Resistors: Built-in or included where applicable.

- Complete Documentation: Control panel wiring schematics, operations manuals, and Bill of Materials included.

- CDMA Duty Ratings: A, B, C, D (standard); E, F, and Long Lift (L) available.

- UL/cUL Labeling: Available (UL508A).

Common Applications

- Overhead Bridge Cranes: For heavy-duty lifting and transporting materials.

- Jib Cranes: Ideal for localized lifting tasks.

- Hoists: Versatile for lifting in various settings.

Related Products

FAQ Section

At Admalite, we understand the importance of providing clear and comprehensive information to our customers. Our FAQ section is designed to address common questions and provide detailed answers about our products and their functionalities. Whether you’re curious about how a hoist controller works or the differences between a hoist and a crane, we’ve got you covered.

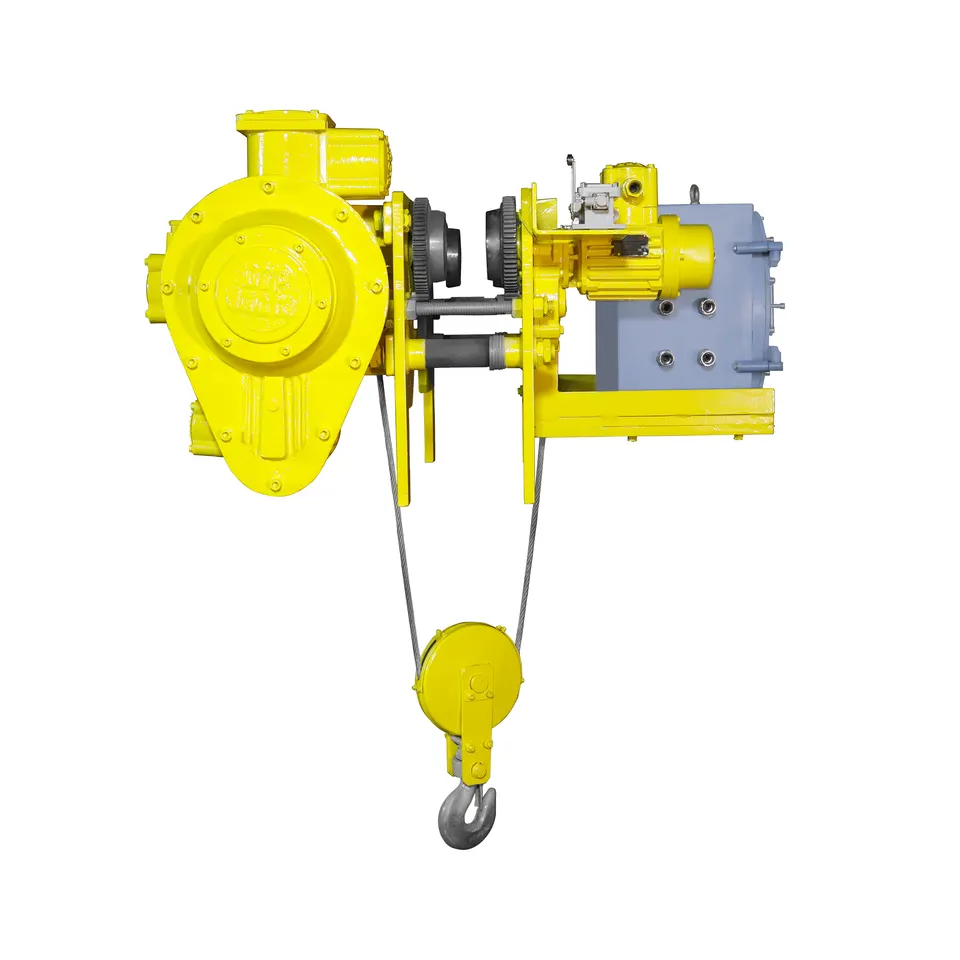

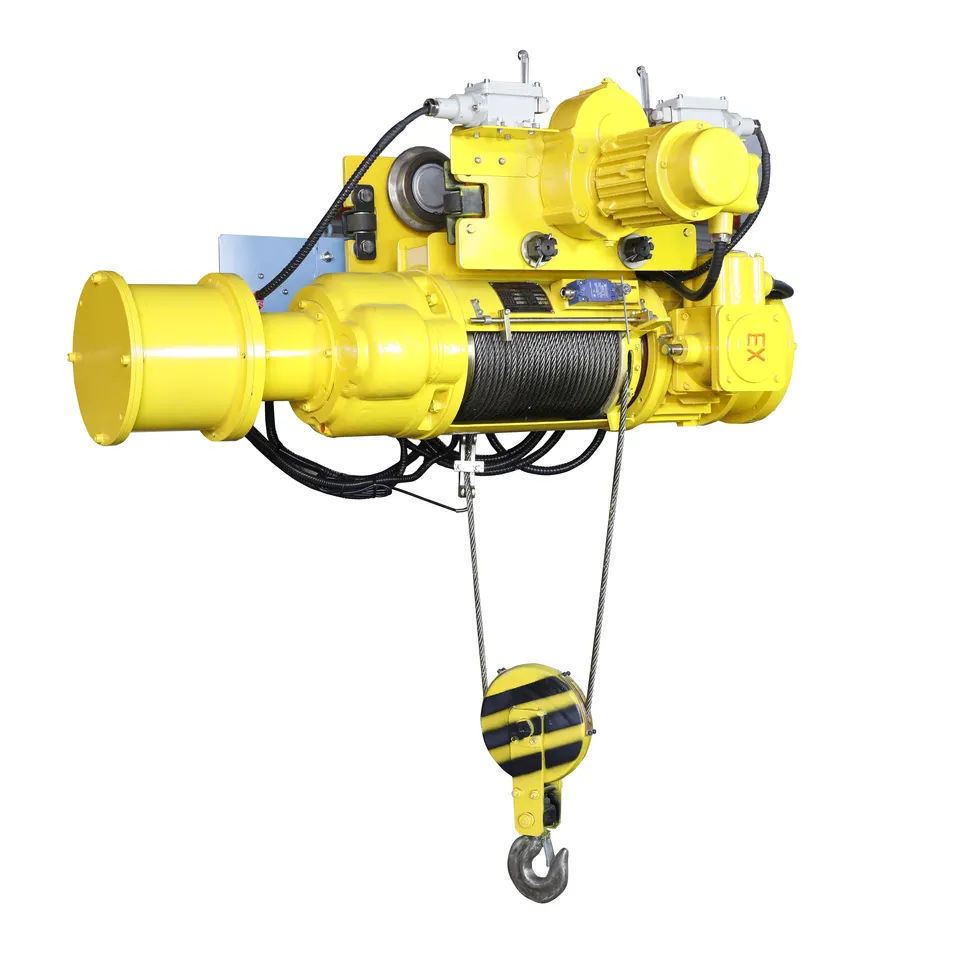

A hoist operates by converting electrical energy into mechanical energy, using a motor to turn a drum or lift-wheel. This action winds or unwinds a rope or chain, lifting or lowering the load.

The main purpose of a hoist is to lift and lower heavy loads safely and efficiently, making it an essential component in many industrial applications.

A hoist is a device used to lift and lower loads, typically within a confined area. A crane, on the other hand, is a larger system that moves loads horizontally and vertically over a wider area.

A crane controller manages the operation of the crane, ensuring precise control over lifting, moving, and placing loads. It integrates safety features to prevent accidents and enhance efficiency.

Basic crane controls include:

- Lift and Lower: Controls the up and down movement.

- Trolley Traverse: Moves the trolley along the crane’s beam.

- Bridge Travel: Moves the entire crane along the runway.

- Manual Control Panels: Operated by human input.

- Automatic Control Panels: Programmed for specific tasks.

- Remote Control Panels: Operated from a distance using wireless technology.

A hoist system works by using a motor to lift and lower loads via a drum or lift-wheel. The system includes various safety and control features to manage the lifting process effectively.

A hoist control system includes all the components and controls necessary to operate a hoist safely and efficiently. This system ensures smooth and precise movement of loads.

A crane control panel is the central system that controls all the crane’s functions, including lifting, lowering, and moving loads. It houses the controls, indicators, and safety devices necessary for efficient crane operation.

A hoist controller manages the movement of the hoist by controlling the motor and other components. It ensures precise lifting, lowering, and positioning of loads. At Admalite, our hoist controllers are designed for optimal performance and safety.

Our expertise in designing and building custom industrial control panels for material lifting equipment ensures that you receive accurate and reliable information. By integrating advanced technology and adhering to high safety standards, Admalite delivers solutions that enhance the performance and reliability of your lifting systems. Explore the answers below to learn more about our innovative control panels and systems, and see how Admalite can meet your specific lifting needs.

Conclusion

Admalite’s custom industrial control panels for Overhead Bridge, Jib Crane, and Hoists are designed to meet the highest standards of safety and efficiency. By choosing Admalite, you’re ensuring that your material lifting equipment operates at peak performance.

OTHER SERVICES

ADMALITE provides a range of services, including installation, maintenance, repair, load testing, customization, upgrades, consultation, replacement parts, and emergency callouts, ensuring their customers’ equipment operates safely and efficiently.

QUALITY GUARANTEE

UL Certification is a globally recognized standard for safety and quality assurance. UL Certification ensures that products and systems meet stringent safety requirements and comply with industry standards.

In the case of ADMALITE, their compliance with UL508A standards for industrial control panels ensures that their products are safe, reliable, and comply with industry standards, giving their customers peace of mind and confidence in the quality of their products.

FREE QUOTE

Do you need help finding out the right hoist? Fill out this form to get in touch.

1100lb. Portable Mini Electric Chain Hoist - Variable Speed

1100lb. Portable Mini Electric Chain Hoist - Variable Speed