Gantry Cranes Overview

In many industrial environments, the ability to safely and efficiently lift heavy loads is crucial. Whether it involves relocating machinery or materials within a factory, loading and unloading shipping containers, or hoisting goods onto elevated storage areas, the importance of using the appropriate equipment cannot be overstated. One such piece of equipment that has gained widespread acceptance in recent years is the gantry crane.

It is crucial to be aware of and adhere to the recommended duty cycle for your specific gantry crane to ensure safe and efficient operation. Operating the crane beyond its recommended duty cycle can lead to overheating and might result in damage to the crane, or cause it to malfunction, increasing the risk of accidents and injuries. By following the designated duty cycle, you can also prolong the crane’s lifespan and minimize the need for frequent repairs or replacements.

Benefits and Insights on Gantry Cranes by Admalite

Admalite, a premier provider of material lifting equipment, specializes in robust and versatile gantry cranes, including models like gantry crane 2 ton, gantry crane 3 ton, and gantry crane 5 ton. Each model is meticulously designed using advanced CAD software and undergoes rigorous load testing before construction, ensuring unparalleled reliability and safety. Discover the benefits and answers to common questions about our gantry cranes.

Engineering Excellence with CAD Software

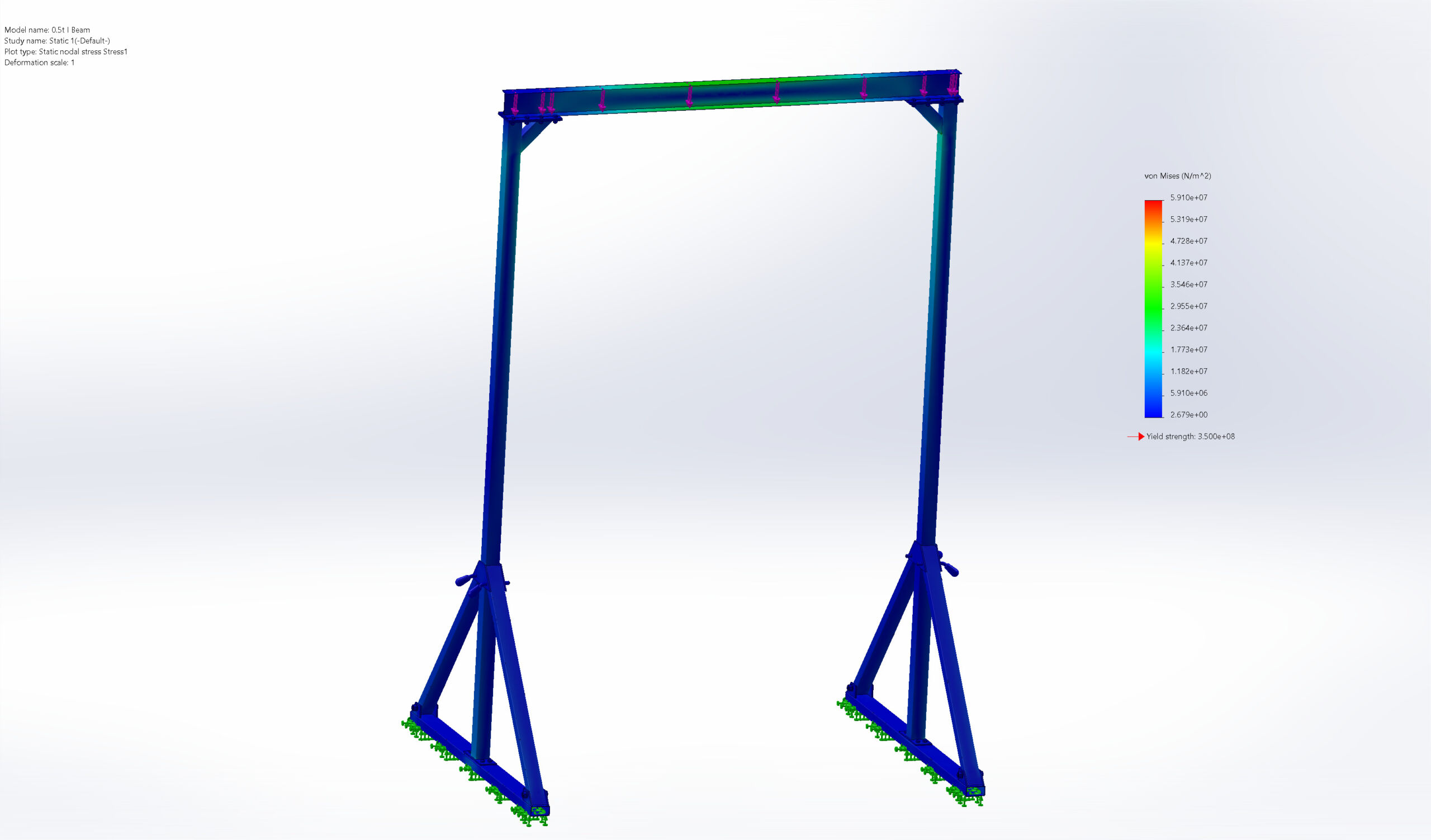

At Admalite, precision engineering is at the heart of everything we do. We leverage state-of-the-art CAD software to design each gantry crane, allowing us to simulate and analyze load conditions and mechanical stresses before any physical model is built. This proactive approach in design and testing ensures that every crane is optimized for both performance and safety.

Uncompromised Safety and Reliability

Safety is a paramount concern at Admalite. Each of our cranes is designed with a minimum safety factor of 4:1, significantly surpassing industry standards. Before leaving our facility, all cranes undergo stringent load testing to verify that they meet our rigorous safety and reliability criteria. This commitment to quality ensures that Admalite gantry cranes are trusted by industries nationwide.

Made in the USA

Our skilled team of welders and metalworkers collaborate closely with our engineers to bring their designs to life, precisely cutting and welding every piece of metal. This meticulous assembly process is conducted entirely in the USA, ensuring that each gantry crane is not only safe and functional but also supports American jobs and manufacturing standards.

Shop Gantry Cranes

Frequently Asked Questions

A crane refers to the entire lifting mechanism, including boom, hoist, and other components. A gantry specifically refers to the structure that supports the crane, typically used to describe the framework in gantry crane systems.

The cost varies based on capacity, span, and customizations. Admalite gantry cranes offer competitive pricing with detailed quotes available upon request, ensuring transparency and suitability for your budget and needs.

While gantry cranes are incredibly versatile, they can be less ideal for operations that require high speeds or extensive vertical lifting because they generally operate at lower speeds and have height restrictions.

The main difference lies in their structure and mobility. Overhead travelling cranes are mounted on elevated runways and move along two rails. In contrast, Admalite gantry cranes are self-supporting and can be moved around on wheels or along a track system.

Dragging a load risks destabilizing the crane, leading to potential accidents. Admalite’s training emphasizes correct handling techniques to prevent such hazards.

Yes, comprehensive training is mandatory for operating any gantry crane safely. Admalite ensures that all operators are proficiently trained and meet or exceed OSHA standards.

It is possible but not advisable to move a gantry crane while loaded due to safety risks. Admalite recommends following operational guidelines and safety protocols strictly.

Admalite gantry cranes offer exceptional portability, adaptability to varied environments, and are capable of lifting substantial loads with ease, enhancing operational efficiency in numerous industrial applications.

The gantry on a crane is the supportive structure that allows the crane to lift and transport heavy materials across the work area.

Admalite Superior Gantry Cranes

With Admalite Gantry Cranes, experience unmatched durability, versatility, and safety. Our commitment to excellence and adherence to the strictest safety standards ensure a reliable and efficient lifting solution for your needs. Contact us today to learn more about our products and how they can help streamline your operations.

A duty cycle table for Electric chain hoists outline the recommended usage time and rest periods for the hoist to ensure safe and efficient operation. The chart below provides an example of duty cycle for an electric chain hoist:

CYCLE PERCENTAGE

CYCLE IN MINUTES

| Duty Cycle | Operating Time | Rest Time |

|---|---|---|

| Class A | 10 minutes | 50 minutes |

| Class B | 15 minutes | 45 minutes |

| Class C | 30 minutes | 30 minutes |

| Class D | 40 minutes | 20 minutes |

| Class E | 60 minutes | 10 minutes |

Note:

The duty cycle classification system can vary depending on the model of the chain hoist. The above table is just an example.

OTHER SERVICES

ADMALITE provides a range of services, including installation, maintenance, repair, load testing, customization, upgrades, consultation, replacement parts, and emergency callouts, ensuring their customers’ equipment operates safely and efficiently.

QUALITY GUARANTEE

UL Certification is a globally recognized standard for safety and quality assurance. UL Certification ensures that products and systems meet stringent safety requirements and comply with industry standards.

In the case of ADMALITE, their compliance with UL508A standards for industrial control panels ensures that their products are safe, reliable, and comply with industry standards, giving their customers peace of mind and confidence in the quality of their products.

FREE QUOTE

Do you need help finding out the right hoist? Fill out this form to get in touch.